Manufacturing Process

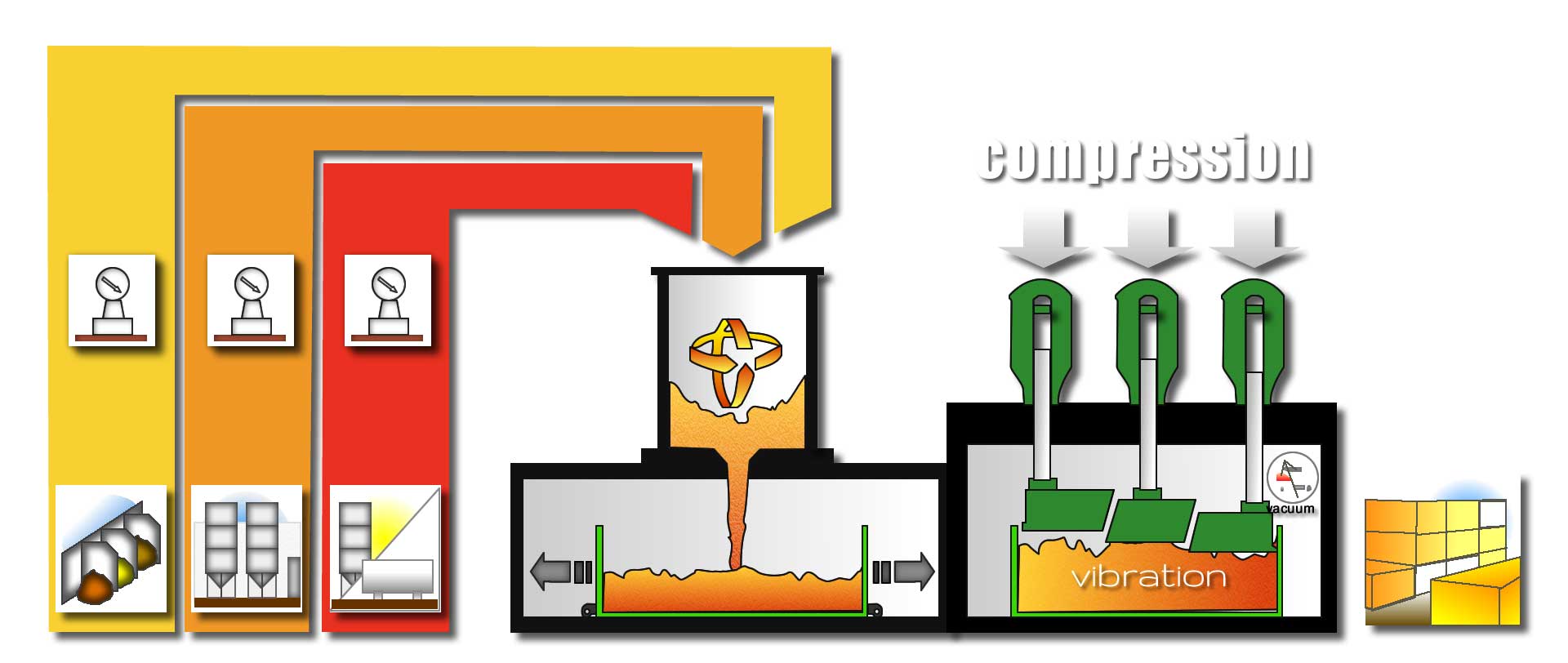

The BRETONSTONE® system technology (patented) has been specially conceived to manufacture stone agglomerate products of the highest quality.

The main phase of the manufacturing process is carried out by the mixture compacting machine using the “vibro – compression under vacuum” process, which makes it possible to work and compact the mixtures using the minimum binding paste to stone material ratio.

In fact, natural stone materials constitute 91 to 96% of the finished product. The major characteristics of the bretonstone system are: correct ratio among the raw material composing the mixture.

- Grit size specially designed to obtain the maximum saturation of the finished product with stone aggregates.

- Absence of air in the mixtures to be compacted and during the compaction phase.

- Simultaneous and modulated action of vibration and compression under vacuum that guarantees the best compaction of the aggregates and the minimum amount of binding paste.

Technical Data

Water Absorption 0.05 ~ 0.25

Applications: kitchen, bathrooms and shopping centres, etc.

Flexural strength mpa. Dry 29.7 (N/mm2) Wet 26.7 (N/mm2)

Standard thicknesses: 8mm - 30mm, depending on application and size.

Sizes: 300x300, 300x600, 600x600, 800x800, 900x900, 920x2420 tiles (all in mm).